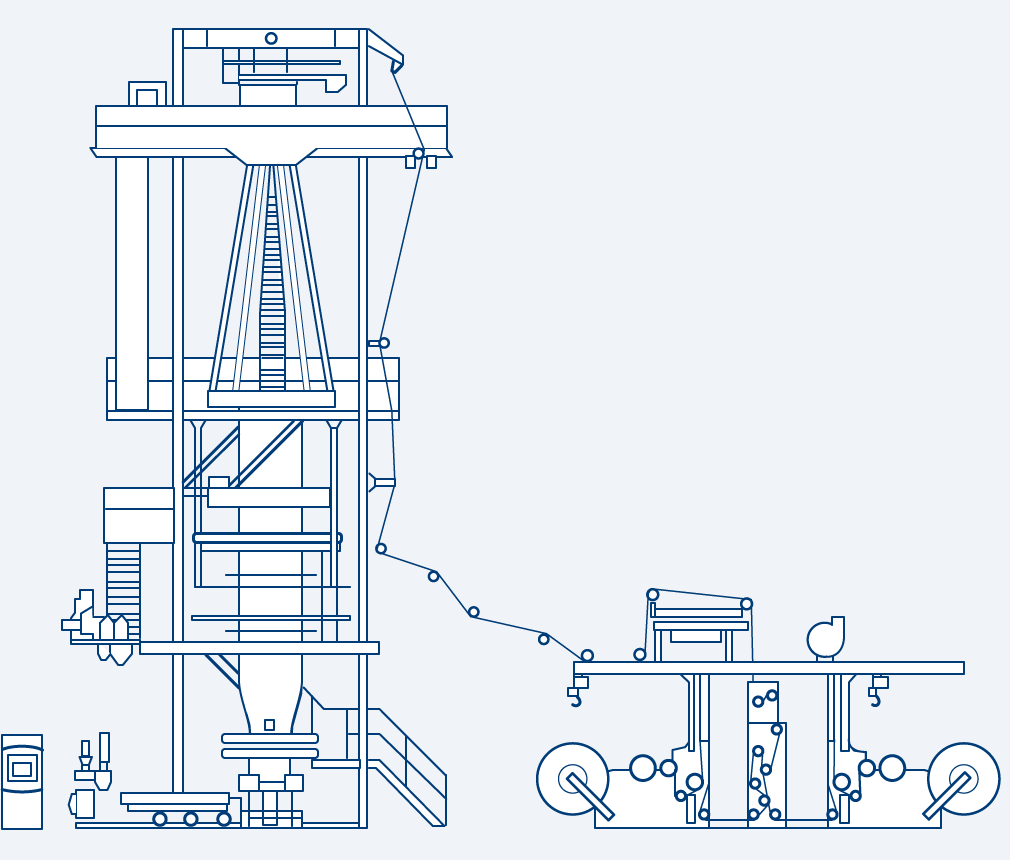

The production process of plastic film is based on the method of film extrusion. The polymer mixture, which consists of granulated primary polyethylene, additives and dyes comes from the storage tank to the screw-cylinder of the extruder, where it is compacted, melted and homogenized. From the screw-cylinder of the extruder, a homogeneous molten polymer mass is fed into the die, where the desired shape is set. The polymer mass is fed through a slit in the extruder die and is inflated to the required size by a constant injection of air using a blowing ring.

The cooled polyethylene film in the shape of a sleeve is folded, stretched through special rollers, if necessary, further drawing of the image, processed by a corona discharge on the activator and wound on a spool into a roll. For cutting a polyethylene sleeve onto a sheet, knives are mounted on extruders.

Extrusion lamination is a technology used to produce simple and complex multilayer compositions based on paper, cardboard, foil and other flexible materials.

In the extrusion coating process, an extruder squeezes the melted thermoplastic through a horizontal slit head onto a moving web substrate. The result is a canvas with a durable coating. The process of extrusion lamination is similar to extrusion coating, however, in this case, the resin is extruded between two substrates and acts as a binder.

Inside the extrusion coating and lamination line, the substrates are melted and compressed in the gluing section. This section consists of a large shaft, a pressure roller and a water-cooled backpressure roller. The combination of pressure between the shafts and temperature provides the required level of adhesion.

The finished product is wound into a roll of multilayer laminated composite. For most plastic films and foil types, a primer coating is required before using them in the extrusion process.

Laminate obtained on equipment for extrusion lamination is very difficult to be stratified into its constituent elements. Such laminate adopts high physical and barrier properties of its components.